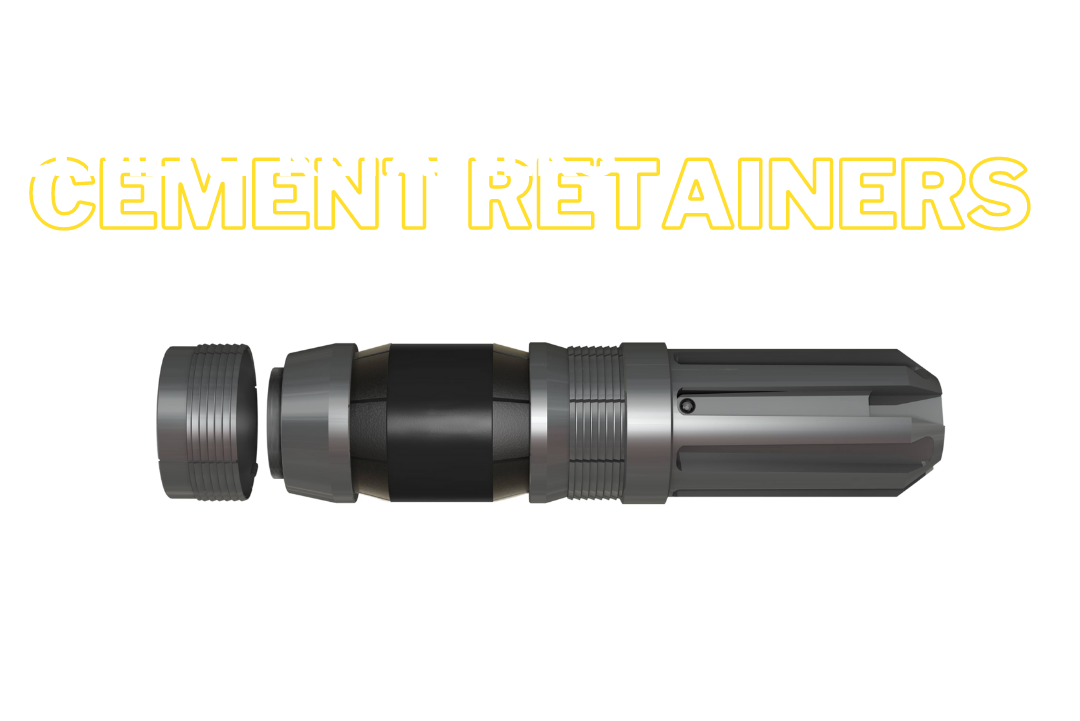

Introducing the Model “A” Ball Check Cement Retainer: a blend of exceptional features and straightforward design. Engineered with a compact profile and small outer diameter, it ensures swift installation. The Model “A” Ball Check Cement Retainer stands out for its affordability, reliability, and unmatched performance in its category.

Free from springs, latches, or sliding valves, its operation remains simple yet effective. A single ball-check functions as a one-way valve, preventing the backflow of fluids from the formation up the wellbore.

Internally, the retainer boasts a finished surface to accommodate a seal nipple for cementing purposes. Positioned at the bottom, the ball-check valve upholds integrity under high pressure and temperatures, ensuring dependable performance in demanding conditions.